Product Information

Core Definition: What is a Hydraulic Breaker?

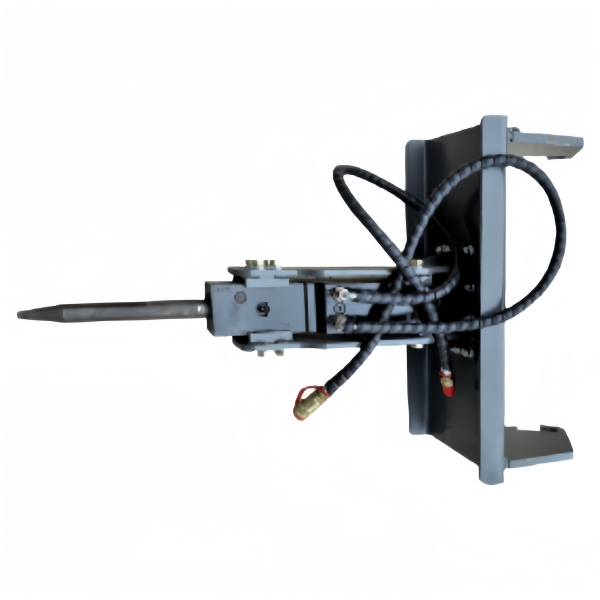

A hydraulic breaker is an impact device installed on an excavator, skid steer loader, or backhoe loader. Its operating principle is to convert the hydraulic energy of the main unit into high-frequency mechanical impact energy, which is then transferred through the drill rod (chisel) to the object to be broken (such as rock or concrete), using the tremendous impact force to crack and shatter it.

Working Principle

At its core is a piston and control valve system. The operating cycle is as follows:

Lifting Phase: High-pressure oil enters the lower part of the cylinder, pushing the piston upward and compressing the nitrogen chamber.

Reversing Phase: The piston moves to a certain position, triggering the control valve to reverse direction, changing the oil flow.

Impact Phase: The high-pressure oil enters the upper part of the cylinder, and the compressed nitrogen expands and releases. These two combined forces drive the piston downward at an extremely high speed.

Impact Phase: The piston violently strikes the rear end of the drill rod, transferring energy through the drill rod to the object being broken.

Return: After the impact is complete, the oil circuit switches again, raising the piston and preparing for the next impact. This process repeats several times per second (frequency), creating a continuous flow of impacts.

The nitrogen chamber acts like a "gas spring," storing energy and assisting in accelerating the piston during the impact phase. This is crucial for improving impact efficiency and protecting equipment.

Core Advantages and Functions

High-Efficiency Demolition: Compared to manual jackhammers or blasting, this tool is tens or even hundreds of times more efficient, making it a core productivity tool for demolition and mining operations.

Precise Control: The operator can precisely control the impact point and force, making it suitable for delicate demolition operations in densely populated areas or near other structures. It is safer and more controllable than blasting.

Versatility: By replacing drill tool shapes (such as flat chisels, tapered chisels, wide chisels, and pavement cutters), it can adapt to a variety of tasks, from fine asphalt crushing to splitting large rocks.

Relatively Environmentally Friendly: Noise, dust, and vibration generated are lower and easier to manage than blasting.

Key Components

Cylinder Body: The core structure that houses all internal components.

Piston: The core impact component, converting hydraulic energy into kinetic energy.

Control Valve: The brains of the hydraulic system, precisely controlling oil circuit switching and hammering rhythm.

Front Head & Accumulator: The front head secures the drill rod. The accumulator absorbs hydraulic shock, stabilizes system pressure, and reduces hydraulic impact on the main unit.

Tool/Mill Point: A consumable part that comes into direct contact with the material being crushed. Made of special alloy steel, it comes in a variety of shapes. "Maintaining the tool" (replacing the drill rod and pin promptly) is key to routine maintenance.

How to Choose the Right Hydraulic Breaker?

Selection must adhere to the principle of "matching," otherwise serious damage to the main unit or hammer can occur:

Carrier Match:

Excavator tonnage: This is the primary factor. Breakers have a recommended weight range. A hammer that is too small will be inefficient; a hammer that is too large can severely damage the excavator's boom, hydraulic system, and structure.

Hydraulic System: The hydraulic flow and pressure of the main unit must be within the range required by the breaker. Flow determines the frequency, while pressure affects the impact energy.

Application:

What are you primarily crushing? Is it soft asphalt or hard granite? This will determine whether you need a light, medium, or heavy-duty breaker.

Brand & Quality:

The machining precision of the internal piston and cylinder, as well as the material heat treatment process, directly determine its durability and reliability.

Well-known brands (such as Soosan and Daemo from South Korea, Furukawa and Okada from Japan, and Aidi Precision from China) offer greater reliability and after-sales service.

After-sales Service: Is the supply of consumable parts (such as drill rods, cups, and seals) timely? Is repair and technical support available?

Key Points for Safe Operation and Maintenance

Avoid running strikes: Triggering the strike without the drill rod firmly pressed against the crushing surface will cause a significant impact force to react on the breaker itself, potentially damaging the piston and front cover.

Maintain Verticality: Keep the drill rod perpendicular to the crushing surface as much as possible to avoid lateral forces, prevent drill rod breakage, and damage to the cylinder.

Regularly check the nitrogen pressure: Nitrogen pressure must be maintained at the specified value. Excessive pressure or low pressure will affect performance and damage the equipment.

Use the correct penetration force: Let the hammer's own weight and impact force do the work; do not use the excavator's arm strength to force it.