Product Introduction

1. Core Definition: What is a grapple bucket?

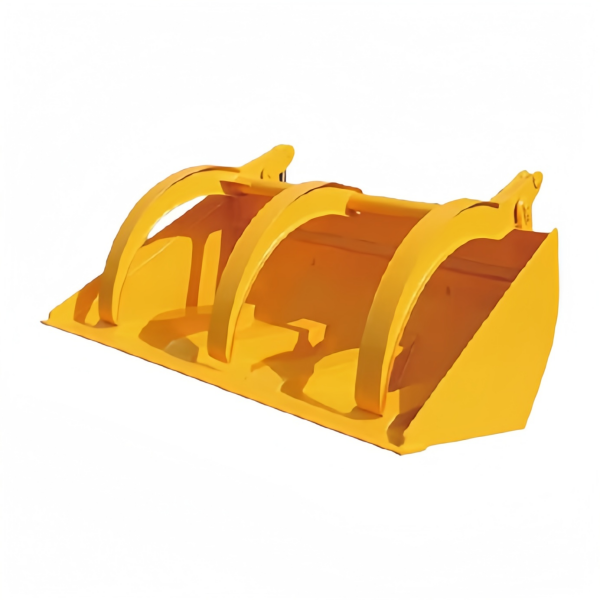

A grapple bucket, often referred to as **** or * in Chinese, is an attachment mounted on an excavator, skid steer loader, or backhoe loader. It is essentially a bucket with hydraulically powered grippers.

Basic Components: A standard bucket for digging, scooping, and carrying materials.

Core Functional Components: Two or more hydraulically powered "fingers" or "grippers" that open and close to grab, hold, carry, and separate materials.

Its significant value lies in combining the functions of an excavator and a gripper, allowing operators to perform a variety of tasks without having to frequently change attachments.

Core Benefits and Features

Versatility: A single machine can be used for multiple tasks, saving the time and cost of purchasing multiple pieces of equipment or frequently changing attachments. Efficiency:

Quick Cycle: Grab, move, and place in a single operation, eliminating the need for repeated shoveling and loading.

Reduced Manpower: No longer requires workers to enter hazardous areas to manually sort or bundle materials.

Sorting & Selection: The gripper can precisely pick out specific materials (e.g., extracting rebar from debris or large rocks from a pile of rocks), which is impossible with a standard bucket.

Secure Material Handling: The gripper securely holds materials, preventing them from falling during handling and improving operational safety.

Clearing & Raking: The closed gripper can be used like a rake to clear sites, level the ground, or separate materials.

How to Choose?

Choosing the right grapple bucket requires considering the following key factors:

Carrier Machine: The model, tonnage, hydraulic flow, and pressure of your excavator or loader determine the size and weight of the grapple bucket that can be used. Primary Application: What material do you primarily handle? Lightweight scrap wood or heavy rock? This will determine the type of gripper you choose (multi-claw vs. dual-claw vs. rock claw).

Material and Construction Quality: Look for products made from high-strength, wear-resistant steel (Hardox, AR400), especially at critical stress points. Thicker steel and better welds mean a longer lifespan.

Rotation: Some high-end grab buckets feature 360° rotation, allowing the operator to adjust the orientation of the gripper without moving the arm. This greatly increases flexibility and efficiency, but also comes at a higher cost.