Product Information

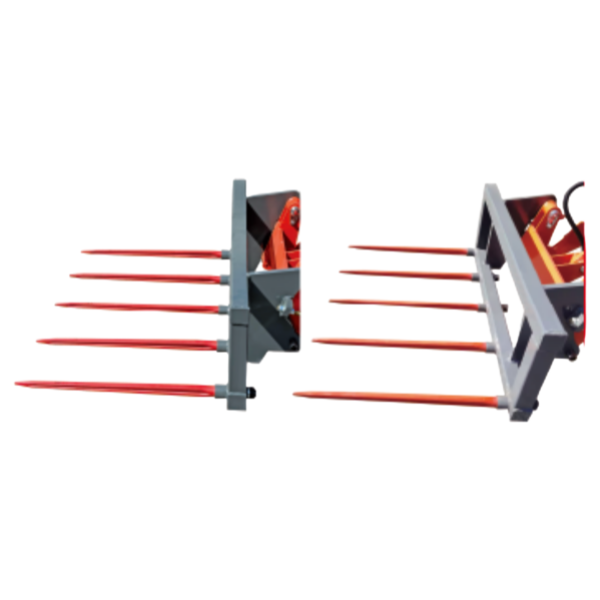

Core Definition: What is a Bale Fork?

A bale fork is essentially a pair (or more) of extended, curved forks, typically mounted on a skid steer loader, telehandler, or tractor front loader. It's designed to penetrate and lift bales, rather than "scoop" them up like a traditional forklift.

Core Benefits and Features

Efficient Handling:

Designed specifically for bales, it significantly outperforms manual handling or forklift operations.

It can handle multiple bales at once (especially platform-type bales), significantly improving efficiency.

Secure & Safe:

The sharp forks easily penetrate the bale, while the curved fork arms act like a "scoop" to support the bale and prevent it from slipping during handling.

This reduces the risk of muscle strain and accidents associated with manual handling.

Stacking Ability:

Allows operators to stack bales to a certain height, maximizing storage space (e.g., in barns and sheds).

Reduced Damage:

Compared to using a bucket or conventional forks, a bale fork causes less damage to bale wrapping (e.g., netting, wrapping) and internal materials (e.g., hay).

Versatility:

Although designed specifically for agriculture, it is also widely used for handling industrial recyclables such as waste paper, textile, and plastic bales.

How to Choose the Right Bale Fork?

Key factors to consider when choosing a bale fork:

Carrier Machine:

Machine Type: Is it a skid steer loader, tractor, or telehandler?

Load Capacity: The lifting capacity of the carrier determines the size and weight of the bale forks you can use, as well as the number of bales you can handle. Ensure that the carrier capacity is greater than (the weight of the bale forks + the total weight of the bales).

Connection Type: Is it a plate or sleeve connection? It must be compatible with the trolley's quick-change mechanism.

Bale Type:

Shape and Size: Are you primarily handling large, small, or round bales? This directly determines whether you should choose a square or round bale fork.

Weight: Bale weights vary greatly for different crops (hay, straw, silage), so you need to choose a fork that is strong enough.

Fork Specifications:

Number of Forks: 2, 3, or 4 forks? More forks provide more stability for handling large square bales.

Fork Length and Spacing: The length must be sufficient to fully penetrate and support the bale. The spacing should be appropriate for the width of the bales you are handling.

Material and Construction: Look for products made from high-strength steel (such as T1 or AR400). Ribs should be added in key areas to ensure they retain their shape under heavy loads.

Additional Features:

Adjustability: Does the fork distance need to be adjusted manually or hydraulically to accommodate different bales?

Tilt: Some square bale forks have an integral tilt feature, making it easier to work on slopes or create tighter stacks.

Tine Type: Replaceable fork tines can be replaced individually as they wear, extending the life of the entire attachment.